In an era defined by a relentless global energy crisis and the escalating threats of climate change, our traditional methods of staying cool are revealing a critical flaw. Air conditioning, while a modern necessity, is a voracious consumer of electricity, accounting for a staggering 15% of global energy consumption and up to 40% in sweltering regions. This creates a vicious cycle: we burn fossil fuels to power our ACs, which in turn exacerbates the very global warming that makes us rely on them more. The search for a sustainable, zero-energy cooling solution is no longer a niche scientific pursuit but a global imperative. Emerging from this challenge is a groundbreaking technology that seems almost like science fiction: Radiative Cooling. This passive, elegant method allows surfaces to cool themselves by shedding heat directly into the cold vastness of outer space, offering a powerful key to a more sustainable future.

The Fundamental Principle: Tapping into the Cosmic Heat Sink

At its core, radiative cooling is a natural phenomenon. All objects with a temperature above absolute zero emit thermal radiation in the form of electromagnetic waves. The fundamental breakthrough of modern radiative cooling lies not in creating this effect, but in mastering and amplifying it through sophisticated material science.

The secret lies in the “Atmospheric Window.” Earth’s atmosphere is largely transparent to certain wavelengths of infrared radiation, specifically in the 8 to 13.5 micrometers (µm) band. This window acts as a one-way channel to the cosmic void, which has a temperature of a mere 4 Kelvin (-269°C). By designing materials that efficiently emit thermal radiation within this specific window, we can enable them to radiate heat directly into space, bypassing the atmosphere entirely.

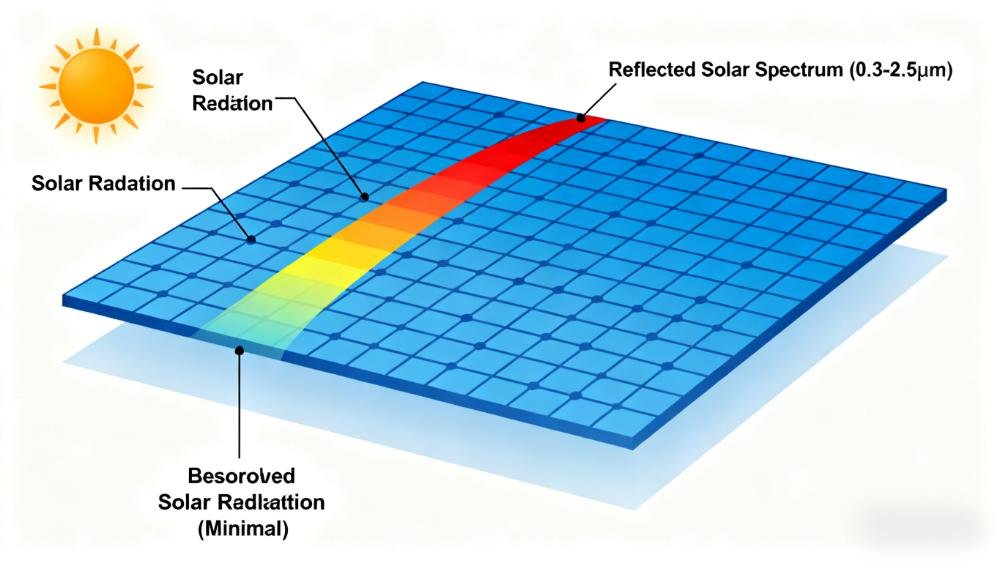

The challenge, however, is twofold. For a material to provide net cooling during the daytime, it must not only be an efficient emitter in the atmospheric window but also be an exceptionally poor absorber of solar energy. The sun bombards the Earth with radiation primarily in the 0.25 to 2.5 µm spectrum. Therefore, the ideal radiative cooling material is an optical maestro: it must possess high solar reflectance (≥92%) across the solar spectrum to reject heat from the sun, combined with high thermal emissivity (≥92%) in the 8-13.5 µm band to efficiently dump heat into space.

The potential is staggering. Theoretical calculations show that a perfect blackbody can achieve a cooling power of approximately 160 W/m² through this window. With optimally designed surfaces, this can lead to surface temperatures dropping 5-10°C below the ambient air, even under direct sunlight. The International Energy Agency predicts that if just 20% of the world’s building surfaces were coated with radiative cooling materials, it could reduce global CO₂ emissions by a monumental 120 million tons annually.

The Material Revolution: Engineering the Perfect Cool

The race to perfect radiative cooling has spurred innovation across three primary material systems, each with unique advantages and applications.

1. Polymer-Based Materials: The Versatile Workhorses

Polymers are a natural starting point due to their intrinsic molecular vibrations (from C-C, C-H, and C-O bonds) that make them strong emitters in the mid-infrared range.

- PVDF-HFP: This fluoropolymer is a star performer. Researchers have created hierarchically porous PVDF-HFP films that achieve a remarkable 96% solar reflectance and 97% infrared emissivity, delivering a sub-ambient cooling of 6°C.

- PTFE (Teflon): Known for its exceptional UV stability and chemical inertness, PTFE is ideal for long-term outdoor use. Advanced assembly techniques have led to porous PTFE coatings with 94% solar reflectance and 93% emissivity, combining performance with outstanding durability and breathability.

- PMMA (Acrylic): Valued for its tunable transparency, PMMA is a prime candidate for smart windows. By engineering a multi-scale structure of micro-pores and nano-pores, scientists have developed PMMA films with 95% solar reflectance and a near-perfect 98% long-wave infrared emissivity, all while maintaining improved mechanical strength.

2. Inorganic Materials: The Durable High-Performers

Inorganic materials like barium sulfate (BaSO₄), titanium dioxide (TiO₂), and aluminum oxide (Al₂O₃) benefit from high electron band gaps that minimize solar absorption and phonon resonances that enhance mid-infrared emission.

- BaSO₄: A team developed a BaSO₄ nanofilm that boasts a phenomenal 97.6% solar reflectance and 96% atmospheric window emissivity, consistently maintaining a temperature over 4.5°C below ambient.

- Al₂O₃ & TiO₂: Research has shown that high-density dispersions of Al₂O₃ in a polymer matrix can achieve over 94% solar reflectance, resulting in a 6.3°C cooling effect. Similarly, multilayer structures using TiO₂ and SiO₂ have been optimized to provide 94% reflectance and a significant 7.2°C temperature drop in subtropical climates.

- CaCO₃: As a low-cost and environmentally friendly alternative, CaCO₃-based paints have demonstrated impressive performance with 95.5% solar reflectance and 94% infrared emissivity, making large-scale deployment economically feasible.

3. Composite and Hybrid Systems: The Best of All Worlds

The most advanced materials often combine components to synergize their strengths.

- Polymer-Inorganic Hybrids: Combining PVDF-HFP with Al₂O₃ nanoparticles has yielded a composite material with 97.5% solar reflectance and 94.8% infrared emissivity, achieving an astonishing daytime cooling of 10.1°C below ambient temperature.

- Function-Enhanced Composites: Researchers are integrating fluorescent materials that convert absorbed UV light into visible light, which is then reflected. This clever “photon down-conversion” trick further boosts effective solar reflectance, adding another layer of cooling efficiency.

- Structurally Optimized Composites: Techniques like electrospinning allow for the creation of core-shell nanofiber mats. These structures create a porous network that scatters sunlight extremely effectively while providing enhanced mechanical strength, crucial for practical applications.

Transforming Industries: The Vast Application Landscape

The potential of radiative cooling extends far beyond a single industry, promising to revolutionize how we manage thermal energy across society.

In Buildings: Slashing Energy Bills

This is the most direct and impactful application.

- Roofs: Applying a radiative cooling coating to a roof can dramatically reduce surface temperature, directly lowering heat transfer into the building. This can lead to a reduction of air conditioning load by 30% or more.

- Walls and Smart Windows: Facades coated with specialized cool paints improve the building’s overall thermal performance. For instance, a modified cement-based coating demonstrated a cooling effect nearly ten times greater than conventional white paint in tropical climates. Meanwhile, transparent radiative coolers for windows can maintain visibility while rejecting solar heat and enhancing radiative heat loss.

In Energy: Boosting Efficiency and Generating Power

- Solar Panels: The efficiency of solar cells drops as they heat up. Applying a radiative cooling layer to the back of photovoltaic panels can lower their operating temperature by over 8°C, increasing electricity output by up to 32% and ensuring more consistent performance.

- Power Generation: By coupling a radiative cooler with a thermoelectric generator, researchers have created a device that uses the temperature difference between the cold sky and the warmer air to generate electricity at night, with power densities reaching 291 mW/m².

- Atmospheric Water Harvesting: In arid regions, radiative coolers can be used to condense atmospheric moisture into drinking water. By cooling a surface below the dew point at night, water vapor condenses and can be collected, with advanced systems using metal-organic frameworks (MOFs) predicting a yield of over 0.25 liters per day per kilogram of material.

In Electronics and Transportation: Smarter Thermal Management

- Electronics Cooling: From computer casings to server cabinets, radiative coatings can passively enhance heat dissipation. One study on a coated aluminum heat sink showed a 25% improvement in total heat transfer coefficient, promising longer device lifespans and reduced cooling fan noise.

- Data Centers: These energy-intensive facilities could see massive savings. A polymer-based porous coating was calculated to save 31% of cooling energy in a simulated data center environment.

- Automotive and Aerospace: A simple coating on a car roof can lower the interior temperature by 7°C, enhancing comfort and reducing the need for air conditioning. In aerospace, where thermal management is critical, tunable emissivity coatings are being developed for spacecraft to maintain stable internal temperatures against the extreme thermal swings of space.

In Textiles and Agriculture: Enhancing Life and Livelihood

- Smart Textiles: Clothing embedded with radiative cooling fibers can offer personal thermal comfort. Advanced fabrics have been shown to lower skin temperature by 0.6-1.0°C during real-world wear tests, a significant benefit for outdoor workers and athletes.

- Agricultural Films: Specialized radiative cooling films used to cover crops can lower root zone temperature by over 12°C and reduce irrigation water needs, while simultaneously enhancing photosynthesis. Field trials have reported yield increases for certain vegetables by more than 127%, offering a powerful tool for food security in a warming world.

Conclusion: A Cooler, Sustainable Future is Within Reach

Radiative cooling technology represents a paradigm shift in our relationship with heat. It moves us from active, energy-intensive combatting of heat to a passive, intelligent partnership with our natural environment. By cleverly leveraging the “atmospheric window,” these advanced materials offer a pathway to drastically reduce our carbon footprint, enhance energy security, and improve human comfort and productivity.

The journey from laboratory prototypes to widespread commercialization is underway. The key challenges of enhancing long-term durability, weathering resistance, and further reducing costs are the focus of intense global research. As these barriers are overcome, we can anticipate a future where our buildings, vehicles, and even our clothing are seamlessly integrated with this zero-energy cooling capability. Radiative cooling is not just a novel material science; it is a foundational technology for building a resilient and sustainable civilization, empowering us to literally cast our excess heat into the cosmic cold, paving the way for a cooler planet.