In the rapidly evolving world of flexible electronics—from bendable displays and wearable health monitors to advanced robotics—the quest for durable and intelligent materials is paramount. Traditional polymers, like polyurethane, have been the workhorses of flexibility. However, they harbor a critical flaw: they are prone to developing micro-cracks and damage from repeated stress, environmental factors, and accidental impacts. These imperfections not only compromise structural integrity but also lead to the eventual failure of the electronic devices they support. While the emerging class of self-healing polymers promises to address this by autonomously repairing damage, they face another significant limitation: they are thermal insulators. In an era of powerful, miniaturized electronics, the inability to efficiently dissipate heat is a recipe for overheating and reduced lifespan. The grand challenge has been to create a single material that seamlessly combines the resilience of self-healing, the compliance of high flexibility, and the essential capability of superior thermal conductivity. Today, groundbreaking research is turning this vision into reality with the development of a room-temperature self-healing Ti₃C₂/polyurethane composite.

The Triple Challenge: Healing, Conducting Heat, and Staying Flexible

The journey to create this ideal material involves overcoming three distinct scientific hurdles.

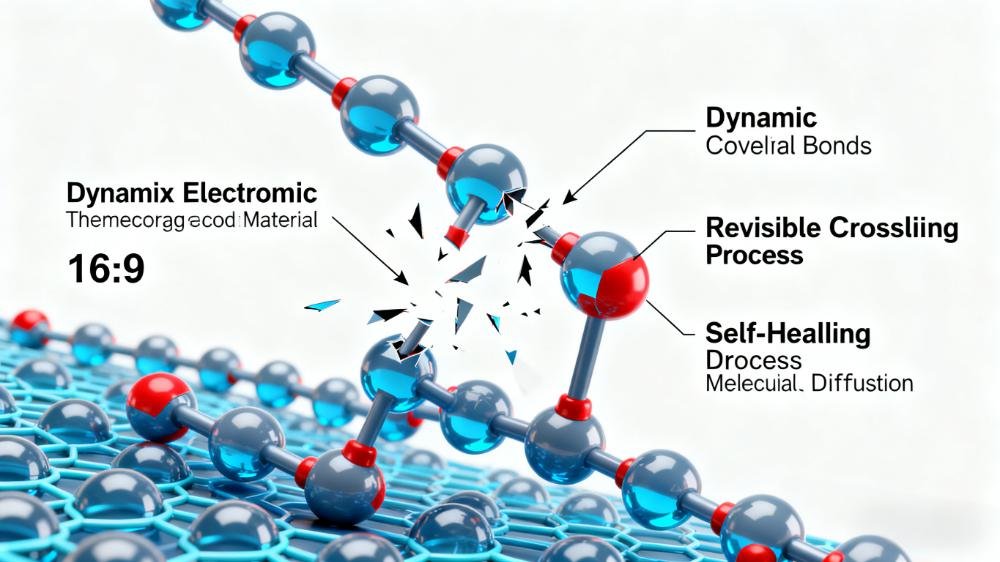

- The Self-Healing Dilemma: Early self-healing materials often relied on “external” agents—microcapsules of glue, for instance—that would rupture and fill a crack. This method is effective but finite; once the capsules in a specific area are depleted, the material can no longer heal itself. The more advanced approach involves “intrinsic” self-healing, where the polymer matrix itself is designed with reversible chemical bonds (non-covalent or dynamic covalent bonds). These bonds can break under stress and then spontaneously re-form at room temperature, allowing for theoretically infinite repair cycles. This dramatically enhances the material’s longevity and slashes maintenance costs, making it ideal for inaccessible applications like internal sensors or protective coatings.

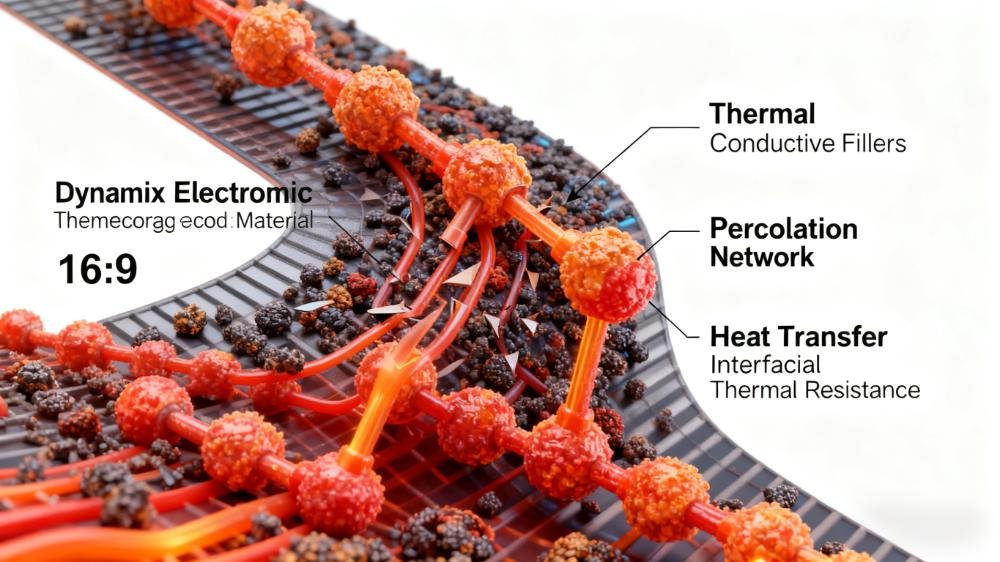

- The Thermal Management Bottleneck: Polyurethane, like most polymers, is a thermal insulator. Its amorphous molecular chain structure and phonon-scattering characteristics result in low thermal conductivity, causing heat to build up in electronic components. The conventional solution is to mix the polymer with highly thermally conductive inorganic fillers, such as metal particles, ceramic powders, graphene, or boron nitride (BN). However, this creates a new set of problems. The rigid filler particles often have poor compatibility with the soft polymer matrix. This incompatibility leads to high interfacial thermal resistance, preventing the formation of efficient, continuous pathways for heat to travel. Furthermore, these rigid particles tend to aggregate, creating stress concentration points that severely degrade the material’s inherent flexibility, making it brittle.

- The Promise and Pitfalls of Ti₃C₂ MXene: Enter Ti₃C₂, a star member of the MXene family. This two-dimensional transition metal carbide boasts a unique layered structure, high specific surface area, and an abundance of surface functional groups. Most importantly, it has an intrinsic thermal conductivity of 57.1 W/(m·K), making it a superb candidate for enhancing polymer composites. Previous attempts to harness Ti₃C₂, however, have struggled with the same issue of interfacial compatibility. For example, compounding Ti₃C₂ with SiC-based phase change materials yielded high thermal conductivity (5.21 W/(m·K)) but poor extensibility. Other methods, like creating sandwich-structured films, improved compatibility but often at the cost of structural integrity during repeated thermal cycling, as the layers were prone to delamination.

A Pioneering Solution: Engineering Order Within Flexibility

The research outlined in the study presents an elegant solution to this trilemma. The strategy involves embedding highly conductive Ti₃C₂ nanosheets into a specially formulated, high-flexibility, room-temperature self-healing polyurethane matrix (SPM). The true innovation, however, lies not just in the ingredients, but in the sophisticated fabrication process.

The Method: A Symphony of Precision Engineering

The experimental process is a testament to meticulous material engineering:

- Crafting the Self-Healing Matrix (SPM): The process begins with the synthesis of the SPM polyurethane elastomer. Using Isophorone diisocyanate (IPDI) and polyether amine (PPGBA) as the main reactants, and Isophorone diamine (IPDA) as a chain extender, a multi-step reaction in a DMF solvent is conducted under controlled temperature and a nitrogen atmosphere. The result is a淡黄色凝胶, which is carefully cast and dried to produce a smooth, flexible SPM sheet. This matrix is fundamentally designed with reversible bonds that enable healing at room temperature.

- Exfoliating High-Quality Ti₃C₂ Nanosheets: The production of the filler is equally critical. The precursor material (TiAlC₂ MAX phase) is etched using a LiF/HCl solution to selectively remove the aluminum layers, creating multilayer Ti₃C₂. This is followed by a meticulous process of washing, centrifugation, and intercalation with ethanol, culminating in ultrasonic exfoliation to separate the layers into individual, high-quality nanosheets. The final product is a “sponge-like” expanded Ti₃C₂, perfect for integration.

- The Masterstroke: Multi-Folding and Hot-Pressing: This is the crucial step that differentiates this research. The synthesized SPM is dissolved and mixed with a precise mass of Ti₃C₂ nanosheets (2%, 5%, 7%, and 10% by weight) in a solvent. The mixture is cast into a film and initially dried. Then, the innovative “multi-fold hot-pressing” technique is employed. The film is repeatedly folded and pressed flat again using a plate vulcanizing machine at 90°C. This ingenious mechanical action forces the Ti₃C₂ nanosheets to align into a highly oriented, layered structure within the polymer matrix.

Why This Architecture is a Game-Changer

The multi-folding process is not just a manufacturing step; it is the key to unlocking high performance. By creating this aligned, lamellar (layer-by-layer) architecture, the researchers successfully built continuous, efficient pathways for phonons—the primary carriers of heat in solids—to travel through the material. This dramatically reduces the interfacial thermal resistance that plagues conventional composite materials, where fillers are randomly dispersed.

Imagine the difference between trying to walk through a dense, random forest versus walking down a series of connected, clear hallways. The aligned Ti₃C₂ nanosheets act as those clear, connected hallways for heat, allowing it to dissipate rapidly and effectively. Meanwhile, the soft, self-healing polyurethane matrix surrounding these aligned layers preserves the material’s overall flexibility and, most importantly, its ability to repair itself. The reversible bonds in the SPM can re-connect across a cut, effectively “stitching” the aligned导热通道 back together.

Remarkable Performance: Data that Speaks Volumes

The results of this novel fabrication method are compelling:

- Exceptional Thermal Conductivity: The composite with 10% Ti₃C₂ loading (SPM-10%) achieved a through-plane thermal conductivity of 4.28 W/(m·K). This represents a dramatic 1,900% improvement over the pristine SPM matrix and is highly competitive with, if not superior to, many existing flexible thermal interface materials (TIMs). This level of conductivity is sufficient to manage heat in high-power flexible devices effectively.

- Outstanding Self-Healing Efficiency: Even with the high filler loading, the material retained its intrinsic ability to heal. The SPM-7% composite demonstrated a mechanical self-healing efficiency of over 88% after being severed and left at room temperature for 24 hours. This means that after being cut completely in half, it could regain 88% of its original strength and flexibility without any external intervention.

- Preserved Flexibility and Stability: The composites maintained excellent tensile strain, capable of stretching significantly without fracture. Furthermore, the material showed remarkable thermal stability and maintained its performance over multiple healing cycles, proving its robustness and durability for long-term applications.

A New Generation of Applications

This convergence of properties opens up a new frontier across multiple high-tech fields:

- Next-Generation Flexible Electronics Thermal Management: This composite is an ideal candidate for use as a thermal interface material in foldable phones, stretchable circuits, and wearable medical devices. It can effectively draw heat away from powerful chips, preventing performance throttling and enhancing device reliability, all while surviving the constant bending and folding of daily use. If a micro-crack forms from fatigue, the material can heal itself, preventing a catastrophic thermal failure.

- Durable Thermal Protection for Batteries: In the flexible and compact batteries powering modern electronics, heat buildup is a major safety concern. A coating of this self-healing composite could serve as a smart thermal barrier, dissipating heat and automatically repairing damage from minor impacts or internal stresses, thereby preventing thermal runaway.

- Advanced Soft Robotics and E-Skin: Soft robots and electronic skin (e-skin) require materials that are flexible, sensitive, and durable. Integrating this composite could solve thermal issues from onboard processors and actuators. If a robot’s “skin” is punctured or cut, the material could seal the breach, restoring both its structural and thermal management functions.

- Intelligent Protective Coatings: For high-value equipment operating in harsh environments, a coating that can dissipate heat and repair scratches or cracks autonomously would be invaluable, drastically reducing maintenance needs and extending service life.

Conclusion: A Material for a Smarter, More Resilient Future

The development of this room-temperature self-healing Ti₃C₂/polyurethane composite marks a significant leap forward in material science. By moving beyond the simple mixing of components to a sophisticated architecture of aligned nanosheets within a dynamic polymer matrix, this research has successfully reconciled what were once considered conflicting properties: high thermal conductivity, superior flexibility, and autonomous self-repair.

This material is more than just a laboratory curiosity; it is a foundational technology that paves the way for a new generation of electronics that are not only flexible and powerful but also incredibly durable and self-sustaining. As research continues to optimize filler loadings and explore other 2D materials, one thing is clear: the future of flexible technology will be built on materials intelligent enough to take care of themselves.