From Regulatory Pressure to Performance Peace-of-Mind: The Waterborne Imperative in Industrial Finishing

The global industrial landscape is undergoing a silent but seismic shift. As environmental regulations tighten and corporate sustainability goals ascend from aspiration to mandate, manufacturers of metal components, machinery, and durable goods face a critical challenge: how to achieve the legendary protection and aesthetic quality of traditional solvent-based coatings while drastically reducing volatile organic compound (VOC) emissions. For decades, the compromise was stark—choose planet-friendly, water-based alternatives and risk performance, or insist on the durability of solvent-borne systems and grapple with compliance, safety, and health concerns.

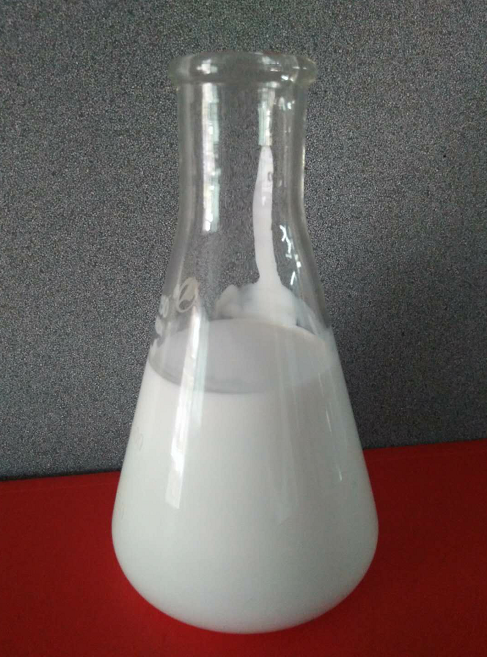

This era of compromise is over. Introducing a paradigm-shifting solution that bridges this historic divide: the IUMRS Water-Soluble Epoxy Resin. This is not merely another water-based emulsion; it is a 95% solid-content, pure chemically hydrophilic water-soluble epoxy resin engineered to deliver uncompromising performance for industrial metal coatings, advanced inks, and demanding adhesive applications, all while championing environmental responsibility.

Beyond Emulsion: The Chemistry of True Water Solubility

Traditional “waterborne” epoxies are often physical emulsions—microscopic droplets of epoxy resin mechanically dispersed in water using surfactants. While an improvement over solvents, these systems can have inherent weaknesses: surfactant migration affecting final film properties, stability issues, and sometimes inferior chemical resistance.

The IUMRS resin represents a fundamental leap forward. It is a true water-soluble epoxy, where hydrophilic segments are chemically bonded into the epoxy polymer backbone itself. At room temperature (0°C and above), it exists as a stable, homogeneous, low-viscosity liquid that readily mixes with water without separation. This molecular-level integration delivers profound advantages:

- Unmatched Stability & Ease of Use: No surfactants mean no fear of seeding, settling, or performance-impairing exudation. It offers a user-friendly experience from factory to application.

- High Film Integrity: The cured film is a pure, continuous epoxy network, free from the weak boundaries or water-sensitive surfactants that can plague emulsions, resulting in superior barrier properties.

- High Efficiency: With a formidable 95% solid content, it maximizes the amount of active resin per gallon, leading to higher build rates, reduced application passes, and lower overall material consumption to achieve the required protective film thickness.

The Technical Blueprint of a High-Performance Workhorse

Specifications tell the story of a resin engineered for excellence:

- Appearance: Colorless to slightly yellow transparent flowing liquid – perfect for clear coats or precise color formulation.

- Epoxy Value: 0.48 – 0.50 eq/100g – Indicates a high concentration of reactive epoxy groups, ensuring a dense cross-link density when cured with appropriate hardeners like waterborne self-leveling agents.

- Viscosity @ 25°C: 1,200 – 3,000 mPa·s – An ideal viscosity range that balances easy handling, pumping, and mixing with excellent flow and leveling properties for smooth finishes.

- Specific Gravity @ 25°C: 1.07 – 1.09

- Key Property: Forms cured films with an outstanding balance of hardness and toughness, resisting both abrasion and impact cracking.

The Performance Portfolio: Where Environmental Meets Exceptional

When formulated into coatings, inks, or adhesives, the IUMRS Water-Soluble Epoxy Resin enables products that defy old perceptions of water-based technology:

- Superior Adhesion & Corrosion Resistance: It forms tenacious bonds with prepared metals (steel, aluminum, galvanized steel), providing a foundational layer that locks out moisture and corrosive agents. Its excellent resistance to acids, alkalis, salts, and chemicals makes it ideal for harsh industrial, automotive, and marine environments.

- High Gloss & Aesthetic Excellence: Capable of producing finishes with remarkable clarity and depth of gloss, meeting the aesthetic demands of consumer appliances, architectural metalwork, and premium industrial equipment.

- Exceptional Durability & Water Resistance: The surfactant-free, densely cross-linked film acts as an impervious barrier, offering long-term protection against humidity, water immersion, and cyclical weathering.

- Formulation Versatility: Its compatibility allows formulators to create everything from flexible primers to hard, chemical-resistant topcoats and everything in between.

Transforming Industries: A Multifaceted Application Engine

This resin is not a niche product; it is a platform technology activating innovation across sectors:

1. Industrial Metal Coatings & Factory-Floor Solutions

- Waterborne Industrial Metal Coatings: The premier choice for coating machinery, agricultural equipment, structural steel, and storage tanks. Offers superior corrosion protection (C5-M level performance possible) with minimal VOC.

- Waterborne Self-Leveling Floor Coatings: Creates durable, seamless, and chemically resistant floors for factories, warehouses, automotive showrooms, and food & beverage plants. Its clarity and leveling are exceptional.

- Waterborne Baking Enamels: Excellent for appliance coatings, automotive parts, and metal furniture, where forced curing enhances performance metrics like hardness and chemical resistance.

2. Advanced Functional Inks & Adhesives

- Waterborne Industrial Inks: Used in high-performance metal decorating inks, can coatings, and durable graphic inks where adhesion, flexibility, and resistance are paramount. Enables vibrant, tough prints on difficult substrates.

- Waterborne Adhesives & Structural Bonds: Serves as a key component in high-strength industrial adhesives for metal-to-metal bonding, composite assembly, and electronic adhesives, offering a clean, strong, and environmentally friendly alternative.

- Sealants & Potting Compounds: Used in electronic sealants and encapsulation to protect sensitive components from moisture, vibration, and corrosive atmospheres.

3. Next-Generation Composite & Specialized Materials

- New Building Materials: As a binder or coating for advanced cementitious composites, prefabricated panels, and anti-corrosion rebar coatings.

- Composite Matrix: For manufacturing lightweight, high-strength composite parts in automotive and aerospace secondary structures.

- Medical Device Coatings: Its purity, durability, and chemical resistance make it a candidate for protective coatings on non-implantable medical devices and equipment housings that require frequent sterilization.

The IUMRS Advantage: Partnership in Sustainable Innovation

Choosing the IUMRS Water-Soluble Epoxy Resin is more than a procurement decision; it’s a strategic partnership in sustainable progress.

- Proven Performance: It delivers the protective pedigree of epoxy chemistry in a future-proof, water-based format.

- Regulatory Confidence: Significantly reduces VOC content, helping your products comply with global regulations (EPA, REACH, etc.) and qualify for green building standards.

- Supply Chain Simplicity: As a non-hazardous material (non-flammable, low odor), it simplifies storage, transportation, and workplace safety protocols.

- Accessible Innovation: We support your journey from concept to production. Start with a 1kg sample to validate performance in your lab, and scale seamlessly to economical 25kg drum quantities for full-scale production.

Conclusion: The Future of Industrial Finishing is Clear, Durable, and Water-Based

The narrative that eco-friendly materials require a sacrifice in performance is obsolete. The IUMRS Water-Soluble Epoxy Resin stands as definitive proof. It empowers formulators and manufacturers to create the next generation of industrial metal coatings, high-performance inks, and resilient adhesives that meet the dual imperatives of planetary stewardship and uncompromising quality.

This is the pure waterborne revolution—where chemistry meets responsibility, and performance flows effortlessly. It’s time to reformulate your future.

Ready to experience the pure difference?

Contact us today to request your 1kg evaluation sample. Our technical team is ready to collaborate with you to tailor formulations for your specific application in waterborne industrial metal coatings, inks, or adhesives. Let’s build a more sustainable, high-performance future together.