In the invisible scaffolding of our modern world, where devices are smarter, vehicles are stronger, and infrastructure endures longer, there exists a class of materials that work silently behind the scenes. They are the unsung heroes of adhesion, protection, and insulation. Among these, epoxy resins stand out for their versatility and reliability. Today, we turn the spotlight on a particularly exemplary formulation: QZ128A Epoxy Resin—a masterfully engineered, colorless to light yellow viscous liquid that is far more than a simple chemical; it is a cornerstone of contemporary manufacturing.

The Essence of Purity and Performance

At first glance, QZ128A presents itself as a model of clarity and consistency. Its appearance as a colorless or pale yellow viscous liquid is more than an aesthetic quality; it is a testament to its high degree of purification. This visual clarity often correlates with superior performance, particularly in applications where yellowness or impurities could compromise the final product’s aesthetics or long-term stability, such as in optical clear coatings or specific electronic encapsulations.

However, the true measure of an advanced epoxy resin lies beneath the surface. Two critical specifications define the elite status of QZ128A: its exceptionally low hydrolyzable chlorine content and its high SSP (Softening Point). Hydrolyzable chlorine, if present in high amounts, can lead to corrosion of sensitive metal components (like microchips), reduce the thermal stability of the cured resin, and impair long-term electrical insulation properties. QZ128A’s minimized hydrolyzable chlorine content makes it a premium choice for demanding electrical and electronic applications, ensuring reliability and longevity.

The Softening Point (SSP) indicates the resin’s thermal characteristics. A suitable SSP, as found in QZ128A, provides an optimal balance between ease of processing at elevated temperatures and the desired rigidity or toughness in the final cured product. Furthermore, its viscosity at 25°C defines its workability—it is meticulously formulated to be pourable, mixable, and processable without being too thin to control or too thick to degas and flow into intricate molds.

A Versatile Performer Across Industries

QZ128A is not a specialist confined to a single niche; it is a multidisciplinary virtuoso. Its molecular architecture grants it properties that are eagerly sought after across a breathtaking spectrum of industries:

- Coatings & Anti-Corrosion: In environments where metal battles relentless forces—from salt spray on offshore wind turbines to chemical fumes in industrial plants—QZ128A forms the heart of protective coatings. It creates a tough, chemically resistant, and adherent shield, dramatically extending the service life of assets and reducing maintenance costs. Its potential colorlessness is a boon for topcoats where specific hues are required.

- Adhesives & Sealants: From bonding composite panels in aerospace to sealing joints in construction, QZ128A delivers strong, durable, and gap-filling bonds. It excels as an encapsulating adhesive and seam sealant, protecting delicate components from moisture, dust, vibration, and mechanical shock. In wind power generation, it is crucial for blade bonding and component protection, ensuring turbines withstand decades of harsh weather.

- Electrical & Electronics Engineering: This is where its low hydrolyzable chlorine truly shines. QZ128A is ideal for electrical insulation, potting of transformers, and encapsulation of sensitive semiconductor devices. It protects circuits from environmental hazards while maintaining excellent dielectric strength, safeguarding the integrity of signals and power in everything from consumer gadgets to grid infrastructure.

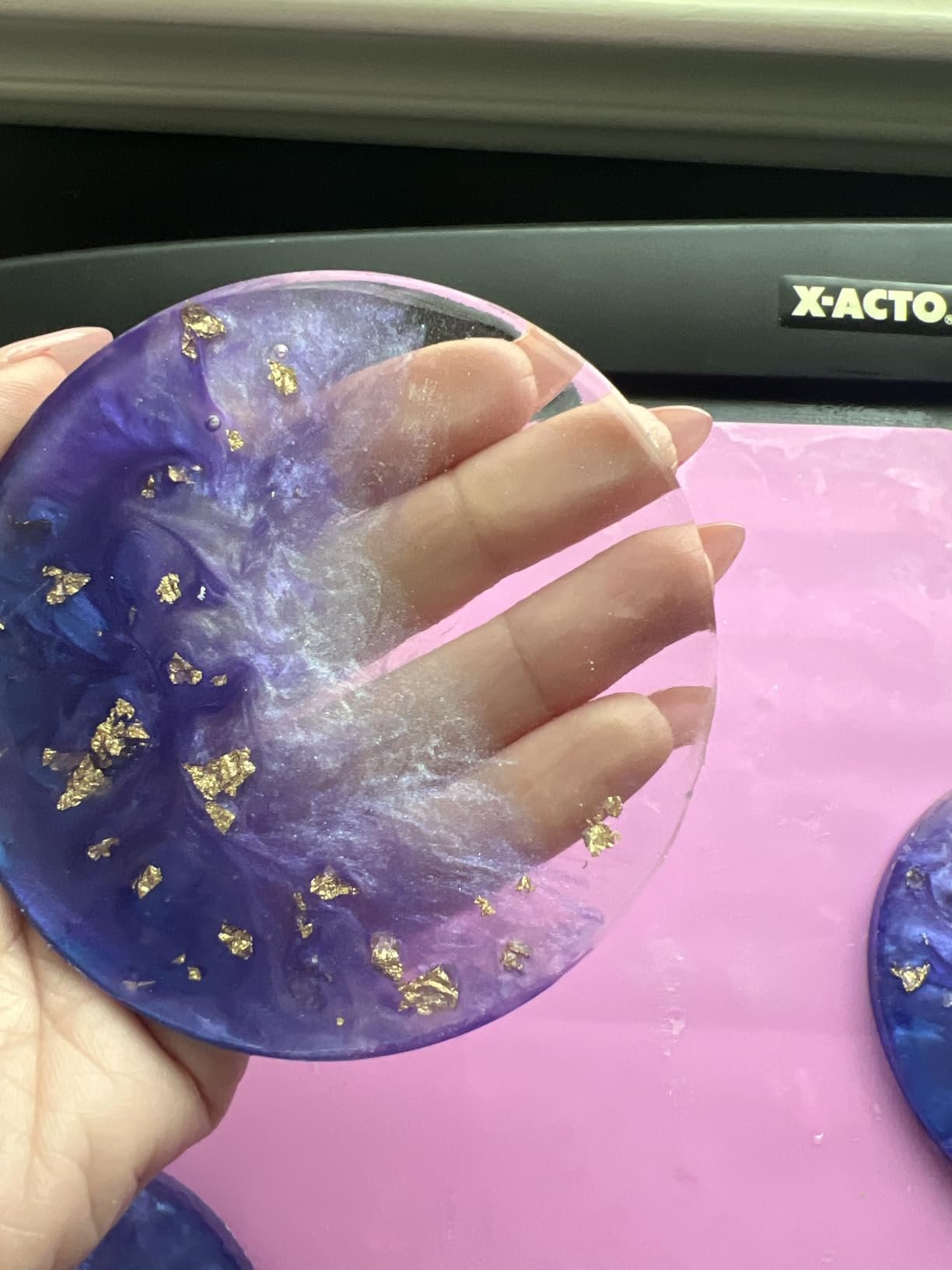

- Composite Laminates & Casting: The world of advanced composites, used in automotive, sporting goods, and industrial components, relies on resins like QZ128A to bind fibers (glass, carbon) into strong, lightweight shapes. In casting applications, its controlled flow and cure profile allow it to create detailed, void-free parts for prototypes, tools, and artistic reproductions.

- The Foundation for Excellence: A Raw Material for High-Grade Resins Perhaps one of its most significant roles is as a primary raw material for processing into other high-grade epoxy resins. Manufacturers value its consistent purity and reactive properties as a starting point for creating customized formulations with even more specialized characteristics, making QZ128A a foundational building block within the epoxy value chain itself.

Commitment to Responsibility and Reach

We recognize that handling advanced materials demands respect. QZ128A, like many reactive chemicals, may be irritating to the skin and eyes. We emphasize a strict safety protocol: immediate washing with water and soap for skin contact, and prompt, copious eye rinsing (for over 15 minutes) followed by immediate medical attention for eye exposure. Safety data sheets and comprehensive handling guidelines accompany every shipment.

Our commitment to quality and global supply is embodied in our strategic manufacturing bases across key industrial zones in China:

- Deqing Yuyue Shuanglin Industrial Park, Huzhou City, Zhejiang Province

- Economic and Technological Development Zone, Shangrao City, Jiangxi Province

- Qingzhu Industrial Park, Yujiang District, Yingtan City, Jiangxi Province

These facilities are equipped with state-of-the-art production and quality control systems, ensuring that every batch of QZ128A meets the stringent specifications our partners depend on. From these hubs, we efficiently serve a global market.

Conclusion: The Invisible Ingredient for Visible Progress

QZ128A Epoxy Resin is more than a specification sheet; it is an enabler. It is the hidden strength in a wind turbine blade braving a storm, the protective shell around a life-saving medical device, the durable bond in a fuel-efficient vehicle, and the insulating guardian of our digital world’s circuitry.

In choosing QZ128A, engineers and formulators are not just selecting a resin; they are investing in a foundation of purity, performance, versatility, and reliability. It represents a partnership with a producer dedicated to both material excellence and responsible stewardship.

As we continue to build a smarter, stronger, and more connected future, materials like QZ128A will remain indispensable. It is the unseen architect, quietly but surely, holding the pillars of innovation together.

Discover the potential that QZ128A can unlock for your next breakthrough. Contact us to explore how this versatile epoxy resin can become the foundation of your success.